|

|

Electrical and Computer Engineering Department |

||

|

Publications, News, Patents,

Talks |

Heterogeneous

Integration Laboratory (HIL) Enabling

~ Integration-Across-Length-Scales-&-Material-Boundaries Through ~ Printing-Transfer-&-Engineered-Self-Assembly Incorporating

~ Nanoparticle/wires-Microscopic-Dies&Chiplets

In

modern science and engineering, the borders between existing fields provide some

of the best opportunities for research. We focus on multidisciplinary,

exploratory research that deals with heterogeneous integration of

nanomaterials and devices across length scale and material boundaries. The

projects can be divided into two trust areas: Heterogeneous

Integration Across Length Scales Through Self-Assembly and Transfer (Trust 1) The first research trust is geared at developing engineered

self-assembly and nanotransfer methods to enable the integration of

functional (electronic and photonic) materials and devices into

heterogeneous systems. The goal is to overcome the scaling limitations

of robotic assembly lines and serial manufacturing. The team pioneered

techniques of self-assembly and transfer demonstrating a number of

different applications. We generally begin with the application and

reverse engineer a unique manufacturing process accordingly that we

license to interested companies. Our engineered self-assembly processes

use surface tension, shape recognition, hierarchies, receptors, and

binding site that can be programmed to direct the assembly (no pick and

place) as well as to from electrical interconnect between the disparate

elements (no wirebonder needed). Demonstrated applications include: Integration

and Characterization of Functional Nanomaterials and Devices (Trust 2) The second research trust follows a

similar theme but exclusively deals with nanomaterials that are formed by

bottom-up synthesis in our lab. The research is geared at the development

of novel techniques to enable the fabrication of future hybrid micro and

nanoscale systems which carry nanomaterial building blocks at exact

locations on a surface. The methods fall in the general area of patterning

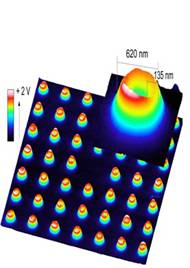

and printing. Our earliest work dates back to the development of scanning

probe lithography methods to pattern surfaces on nanometer scale. Today

scanning probe allows fabricating prototypes of devices such as single

electron transistors. More recent research has focused on parallel

methods to pattern, print, or integrate nanomaterials with sub 100 nm

precision. |